1.

WHY SHOULD WE SHEAR SHEEP?

Shearing must be practiced for the health and hygiene of each individual animal.

Unlike other animals, most sheep are unable to shed. If a sheep goes too long

without being shorn, a number of problems occur.

The excess wool impedes the ability of sheep to regulate their body temperatures. This can cause sheep to become overheated and die.

Urine, faces and other materials become trapped in the wool, attracting flies, maggots and other pests. This causes irritation, infections and endangers the health of the animal.

Sheep with large amounts of wool can become immobilised by physical obstacles in their path and are more susceptible to predator attacks.Preparation for Shearing

o Don't use any

non-approved non-scourable marking crayons or colour

sprays in the weeks

leading to shearing.

o Don't use any insecticide chemical on the fleece for 6 weeks

before shearing.

o Remove all collars from pet sheep.

o Remove any foreign material from the fleece (leaves, pieces of

wire, hayseeds, etc.)

o Warn shearers of any ear tags.

The Act of Shearing, and there after

o Shearing can be stressful for sheep.

o Shearing requires skill to shorn efficiently and quickly, without causing harm to sheep or shearer.

o Try not to feed sheep the night before shearing so their stomachs are empty making it more comfortable for them while being shorn.

o Because newly shorn sheep become colder faster, place them in paddocks with windbreaks and plenty of pasture.

o The best time to apply louse and fly strike prevention treatments is right after shearing.

o Providing sheep with coats or covers are a good option on small farms when the weather is cold or wet.

"To be a good shepherd is to shear the flock, not skin it"

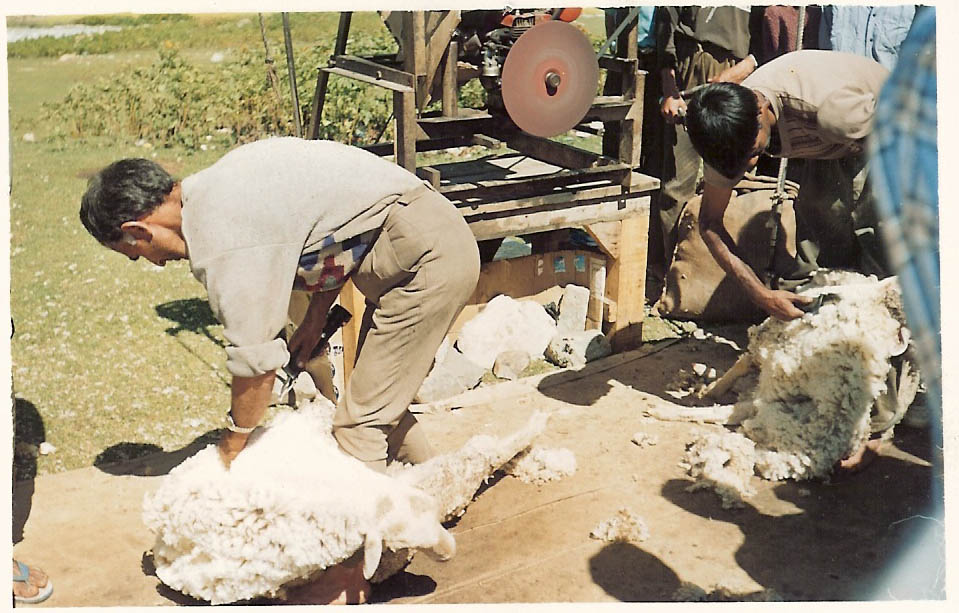

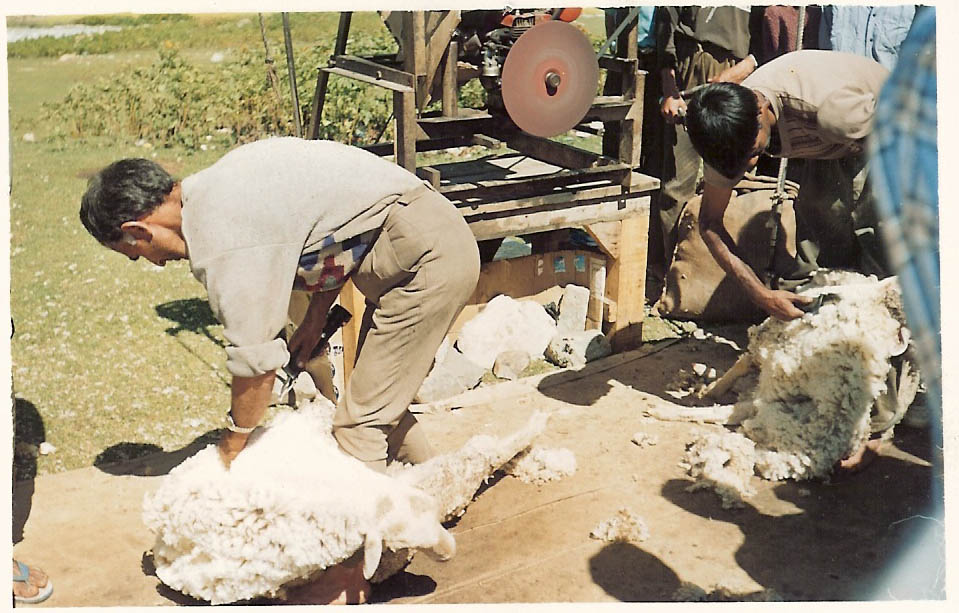

2. SHEARING OF SHEEP

Sheep make a valuable contribution to the livelihood of the

economically weaker sections of the society especially in the

mountainous areas by its multifaceted utility of producing wool,

meat, hides and manure etc. Wool is an important product of

sheep which continuously grows on it and its utility and value

depends upon its quality. The fibre fineness and the staple

length are two very important characteristics of the wool

determining its value and utilisation. The finest wool with good

staple length is used in the worsted system of yarn production

and for manufacture of best quality suiting. Kashmir Merino

developed in Kashmir is a fine wool breed of sheep comparable to

the best wool breeds of the world. Its wool has a fibre diameter

of 21 to 22 microns which is considered as the best by all

standards.

The act of cutting or removal of wool from the body of sheep is

termed as shearing. Sheep are washed at least two days before

shearing in order to remove dirt, suint and grease which hinder

shearing. Shearing is generally done twice a year in Kashmir

during spring and autumn months. Some producers prefer to shear

pregnant ewes before lambing. If ewes cannot be completely shorn

before lambing, they should be “crotched out” by shearing

the wool from the udder and dock area and from the head and eyes

of those breeds with wool on the face. This will make lambing

and nursing easier. Shearing before breeding in summer season

tends to increase the heat loss from the body and cools the ewe

and ram, thus inducing oestrus in the ewe and stimulating

spermatogenesis in the ram. The traditional way of clipping

wool is the hand shearing by using shearing scissors. It is now

an out dated practice and is getting replaced by machine

shearing.

Shearing doesn't usually hurt a sheep. However, shearing

requires skill so that the sheep is shorn efficiently and

quickly without causing cuts or injury to the sheep or shearer.

Most sheep are sheared with shears or shearing machines. The

fleece is removed in one piece. Some sheep are sheared manually

with scissors or hand blades. While some farmers shear their own

sheep, many hire professional sheep shearers. In many countries,

including the United States, there is a growing shortage of

qualified sheep shearers. Many states hold annual sheep shearing

schools. A professional shearer can shear a sheep in less than 2

minutes. The world record is 37.9 seconds. It was set in 2016 by

Ivan Scott from Ireland.

"It is the duty of a good shepherd to shear his sheep, not to

skin them". (Tiberius)

3. METHODS OF SHEARING:-

1 Hand shearing

2 Machine shearing

Hand shearing:

Blade shears consist of two blades arranged similarly to scissors except that the hinge is at the end farthest from the point (not in the middle). The cutting edges pass each other as the shearer squeezes them together and shear the wool close to the animal's skin. Blade shears are still used today but in a more limited way. Blade shears leave some wool on a sheep and this is more suitable for cold climates such as the Canterbury high country in the South Island of New Zealand where approximately half a million sheep are still shorn with blade shears each year. For those areas where no powered-machinery is available blade shears are the only option. Blades are more commonly used to shear stud rams.

Machine shearing:

Machine shears, known as handpieces, operate in a similar manner to human hair clippers in that a power-driven toothed blade, known as a cutter, is driven back and forth over the surface of a comb and the wool is cut from the animal. The original machine shears were powered by a fixed hand-crank linked to the handpiece by a shaft with only two universal joints, which afforded a very limited range of motion. Later models have more joints to allow easier positioning of the handpiece on the animal. Electric motors on each stand have generally replaced overhead gear for driving the handpieces. The jointed arm is replaced in many instances with a flexible shaft. Smaller motors allowed the production of shears in which the motor is in the handpiece; these are generally not used by professional shearers as the weight of the motor and the heat generated by it becomes bothersome with long use.

Advantages of Machine Shearing over hand shearing:

It is less time consuming as it requires just 4 to 5 minutes for shearing of each animal against 20 to 30 minutes by hand shearing.

It causes a smooth or uniform shave over the animal body as against hand shearing where the wool cut is irregular.

Staple length is more in mechanical shearing than in hand shearing.

Chances of injuries and wounds in mechanical shearing are less than in hand shearing.

It does not exert stress on and is convenient for the animal as compared to hand shearing.

Machine shearing is a value addition to the wool and it fetches more prices.

Prevent buildup of manure and urine that can lead to parasitic infection.

4. PROCEDURE OF MACHINE SHEARING IN SHEEP

1) The sheep must be held properly in a comfortable position to prevent its struggling during shearing. Most shearers use the method in which the sheep is set upon its rump and supported firmly between the shearer's knees.

2) The skin should be stretched so that it is smooth in the area being shorn.

3) Wool fibres should be cut only once next to the skin to avoid "second cuts" or short fibres of reduced value.

4) Belly wool, leg wool and tags have a lower value and should be kept separate from the higher-quality wool from the back, neck and sides.

5) The fleece should be removed in one piece so that it will remain together when tied.

6) The fleece should be tied only with paper wool twine to prevent contamination.

Step by Step Procedure of Shearing

|

Catching and Holding |

Start at the top of the brisket |

Move to the first back leg |

Don't forget the tails |

The undermine |

The neck |

The Shoulders |

The long blows |

Cheek and right front leg |

The Final Sweeps |

5. PRECAUTIONS DURING MACHINE SHEARING OF SHEEP

1) Cutters and combs should be sharp; and they should be cleaned, resharpened and lubricated after each job of shearing.

2) The shearing floor should be clean and free of straw or chaff. It should be swept clean of second cuts and manure tags after each shearing.

3) Sheep must be dry before shearing. Wet wool tends to heat up and become discoloured.

4) Be extremely careful when shearing around the udder, scrotum, sheath, loose skin of the flank and hamstring.

5) Never lift the unshorn fleece with the left hand and attempt to shear it off. This lifts the skin as well, which will be cut in shearing. Instead, use your left hand to stretch the skin away from the shearer.

6) Use a shearing glove on the non-shearing hand to protect yourself against injury from the handpiece.

7) Keep the electric cord of the shearer behind you so that it cannot be cut, thus preventing electric shock.

8) Do not rush through the shearing procedure in an attempt to increase speed. The appearance of the shorn sheep (which should have a minimum of cuts) and the condition of the fleece are as important as speed. An experienced shearer can shear a sheep in 5 minutes or less, which works out to about 100 sheep per day.

9) Newly shorn sheep should be protected from the cold and rain until they have had time to regrow some wool cover.

6. PREVENTION OF WOUND BREAKDOWN IN SHEEP SHEARING WOUNDS

Shearers should take care to avoid causing shearing wounds. When stitching a large shearing wound, shearers can minimize the risk of contamination and assist the healing process by taking the following steps:

- Keeping needles and cotton in antiseptic solution

- Washing the wound site and your hands with a suitable antiseptic solution

- Keeping stitches less than 3cm apart

- Spraying the stitched wound with a suitable antiseptic spray

- Marking the sheep so it can be easily identified and the healing wound can be assessed. Usually, a wound is completely healed between two and four weeks, depending on its size and location. Severe wounds that involve more than the skin layer (deep hamstring wounds or open belly wounds) and wounds to sensitive areas (the pizzle and teats) are painful and stitching must not be attempted. Seek immediate veterinary advice or humanely euthanase the animal.

Sheep suffering pain or distress from any severe wounds or wound infections must not be transported. If you are unsure whether or not the animal is fit to load, seek veterinary advice.

DIPPING

Dipping means putting or washing animal in medicated water in order to cure or prevent from ectoparasites, sheep scab, mange, get clean wool, remove waste materials and dung from fleece and keep away sheep blow flies. It is usually done once in a year before post winter shearing or before post autumn shearing. It is also done when the incidence of ectoparasites is high. After about 10 days shearing is followed by dipping.

Methods of Dipping:

A. Hand bath: it is used for small flock. Sheep are lifted one by one into a tank of galvanized iron (1.2 x1.0x0.5 m) and kept for 2 minutes. Sheep are then placed on drain board to drain off surplus dip back into tank.

B. Swim bath: it is used for large sized flock. Two to three sheep are dipped at a time. Examples:

Injectibles: Ivermectin, Doramectin and Moxidectin (@200 μg/kg b.w s/c ) in Late spring (1 to 31 May) and late autumn (1st to 30th November ).May be repeated after 7-15 days, if needed, in case of severely affected animals.

Insecticides: like Diazinon (0.01%), Flumethtrin (0.5%),

Coumaphos (0.1%). Spraying or dipping with insecticides may

be repeated in case of heavy infestations as per

circumstantial evidences

Precautions:

1. Avoid dipping in advanced stage of pregnancy.

2. Always water the sheep before dipping to avoid drinking of dip solution.

3. Avoid dipping on rainy days so that dip may not be washed off.

4. Avoid dipping of sick animals, animals with wounds and young lambs.

5. Avoid dipping in rams in breeding season to guard from injury to pen